rockwell b-scale hardness testing|rockwell hardness scale for aluminum : tv shopping • Brinell hardness test• Hardness comparison• Holger F. Struer• Knoop hardness test See more

28 de fev. de 2021 · 30 Minute compilation of Blaze and his Monster Machine friends saving the day! Get ready for an action packed time as Blaze transforms to keep Axle City out .

{plog:ftitle_list}

WEBOnlyFans is the social platform revolutionizing creator and fan connections. The site is inclusive of artists and content creators from all genres and allows them to monetize their content while developing authentic relationships with their fanbase. Just a moment. We'll try your destination again in 15 seconds .

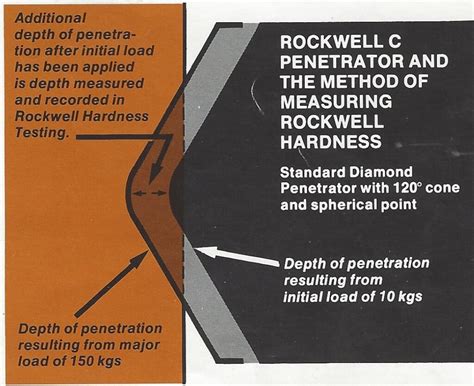

The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). There are different scales, denoted by a single letter, that use different . See moreThe differential depth hardness measurement was conceived in 1908 by Viennese professor Paul Ludwik in his book Die Kegelprobe (crudely, "the cone test"). The differential-depth method . See moreThe Rockwell hardness test can be conducted on several various hardness testers. All testers, however, fall under one of three categories. Bench model hardness testers can be found . See moreThere are several alternative scales, the most commonly used being the "B" and "C" scales. Both express hardness as an arbitrary See more

• International (ISO)• US standard (ASTM International) See more

• Brinell hardness test• Hardness comparison• Holger F. Struer• Knoop hardness test See more• Video on the Rockwell hardness test• Hardness Conversion Chart• Rockwell to brinell conversion chart• Hardness Conversion Table See more

While the Rockwell hardness testing scale is prevalent, it is best to consider the material thickness and softness to select the most suitable scale between Rockwell B (HRB) .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as .The Rockwell test is based on measurement of the depth of penetration with the hardness number read directly from the dial gauge or digital display that is part of every tester. In . The equation for the Rockwell hardness test for metals is below: d=depth from zero load point. N and s = various scale factors that can be found in the chart below. Rockwell A scale. Used to test: Tungsten carbide. Rockwell .

understanding rockwell hardness scale

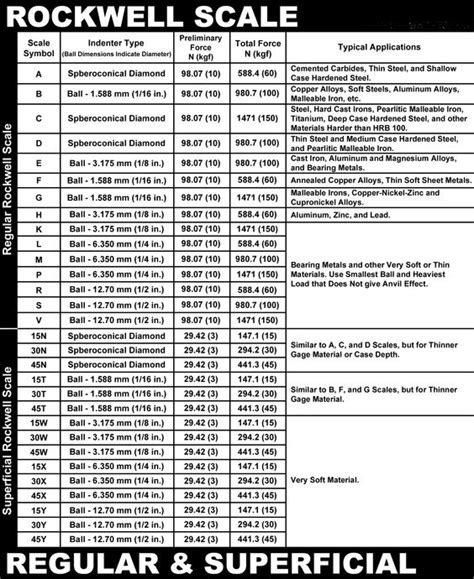

This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges .Rockwell Hardness Testing Reference Guide. ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your .Rockwell hardness testing is a useful and efficient way to determine the hardness of a material. It measures the depth of penetration of an indenter on the material being tested, making it possible to calculate its relative hardness and .

The Rockwell hardness test is used for macro hardness tests, which are generally defined as tests that use indentation loads below or equal to 1 kgf. Therefore, a ground surface is usually sufficient, and sometimes no .Definition of the Rockwell hardness test method The Rockwell hardness test methods are described by a number of scales, characterized by a standard, an indenter type, and a load. Examples of Rockwell hardness test methods: .Rockwell hardness test using Rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc, aluminum, cemented carbides, iron, titanium, .Rockwell scales allow you to follow the standard scale tables and rules to get the accurate values of the hardness of your test material. + 86 755 61301520 [email protected]

Rockwell hardness test into what is today the most widely used method for acceptance testing and process control of metals and metal products. Since its development, the popularity of the Rockwell hardness test has steadily grown. The Rockwell hardness test continues to be applied as a tool for

s is either 0.001 mm or 0.002 mm, depending on the Rockwell hardness scale used N is either 100 or 130, depending on the Rockwell hardness scale used Rockwell hardness testing with United Testing Systems. Some of our most popular test and inspect solutions that offer Rockwell hardness testing from United are: TRU-BLUE II Rockwell Hardness Tester

See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .The Rockwell hardness B scale used for soft or mild metal materials, is the second most common hardness scale in the testing field. The information provided in this article is likely to be enough for you if you want to proceed with this test for hardness deduction purposes.

Bottle Wall Thickness Tester service

A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale . The scale follows an even subdivision of 0.002 mm (2 µm), so that reaching half the reference depth also corresponds to half the maximum hardness value (Rockwell hardness value 50). When diamond cones are used, the Rockwell scale is .Set includes six files and a chart to convert to Vickers scale. It is an economical way to determine the hardness of steel on the Rockwell C-scale.Handles are marked with Rockwell hardness values. If a file can scratch your material, then your material is softer than the file. If a file cannot scratch your material, then your material is harder than the file.

Hall Effect Thickness Gauge (Bottle Thickness Tester) service

Find the hardness conversion for Rockwell B scale or high hardness range here. Download as PDF or get the Rockwell conversions right away.The Rockwell scale is one of the standard methods used to measure a material's hardness. The scale has different numbers that represent hardness based on the indent's depth caused by the test material's indentation. Let us look at how you can measure and read Rockwell's hardness value in this article.How To Operate The Analog Rockwell Hardness Tester ; Cylindrical Correction Chart; Hardness Conversion Chart - Rockwell "B" Hardness Range; Hardness Conversion Chart - Rockwell "C" Hardness Range; Hardness vs Minimum Thickness Chart; Rockwell Scale-Indenter-Load Chart; Contact Us. About Us; Store Policies; Blog

Scale C (carbide) testers are used for testing cemented carbides in the Rockwell A Scale, where tolerances of ± 0.20 of a Rockwell Hardness point are required. A specially selected “A” Brale penetrator is used to measure the hardness of cemented carbides in accordance with ASTM B 294 and the Cemented Carbide Producer’s Association (CCPA).Usually soft materials like 1018 mild steel will use the Rockwell B scale, which makes use of a 1/16″ rounded steel penetrator with a 100 Kg major load. Hardened or alloy steel will use the Rockwell C scale, which uses a diamond .Rockwell hardness test for plastics: In this test, a load of 15 or 30 kg is applied to the surface of the plastic material for a few seconds. . Rockwell B scale (RHB): This scale is used for testing harder materials, such as brass, mild .Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf . 1822: The Mohs scale for .

In conversion scales, common terms which should be first understood are scales, symbol, indenter and load or test force. All of these tables are based on these terms. For any hardness test, these tables are used for conversion of values from one test to another to get accurate results. . Rockwell B Hardness Range Hardness Conversion Chart for .The various indenter types combined with a range of test loads form a matrix of Rockwell hardness scales that are applicable to a wide variety of materials. Rockwell B and Rockwell C are the typical tests in this facility. The Rockwell B penetrator is a 1.59mm (1/16 inch) diameter tungsten-carbide ball and the major load is

rockwell testing chart

Variants on the Rockwell hardness test procedure are used depending on the material and strength of a part. The most common Rockwell variants include: HRC – Known as “Rockwell C,” a 150 kgf load is applied via a diamond in this method. ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness .Rockwell Hardness tester, such as Wilson Model 524T Rockwell Hardness Tester, or equivalent, with diamond brale 120° cone or 1/16 inch diameter carbide ball . When testing on the Rockwell B scale, if the HR value of an indentation exceeds 100 points, change the indenter ball. Make one indentation on a test block to seat the Rockwell hardness testing is somewhat comparable to Brinell hardness testing, in that it measures a metal’s resistance to penetration, . For example, B scale, which uses a 1/16 inch ball diamond indenter under a total test force of 100 kgf, is applicable to copper alloys, soft steels, aluminum alloys, and malleable iron.

What is the Rockwell Scale? Rockwell hardness testing is the most commonly used hardness testing method to measure the permanent depth of an indentation, which is finally compared to the Rockwell scale to derive the hardness number. . while low hardness range involves Rockwell B Scale. The below mentioned chart will highlight the hardness . If the hardness exceeds this range, use Rockwell hardness A scale (HRA). If the hardness is below this range, use Rockwell hardness B scale (HRB). The upper limit of Brinell hardness is HB650; it cannot exceed this value. 4. The indenter for the Rockwell hardness tester C scale is a diamond cone with a 120-degree apex angle.Normally the B and C scales are used on stainless steels, B for softened steel and C for hardened steel. Hardness conversions between different scales. There are several hardness scale conversion systems, including BS 860 and ASTM E140. The table shows a set of values that has been used for stainless steels and also includes a tensile strength .

The calculator has two modes — calculate and convert.The calculate mode is helpful if you have the indentation depth and want the Rockwell hardness number for either scale B or C. The convert mode is for converting Rockwell hardness numbers to a different scale like Brinell or Vickers.. The hardness data can not be presented in terms of a universal .

rockwell hardness scale for steel

WEB5 dias atrás · An dieser Stelle noch ein kurzer Hinweis: Tipico Casino Bonus Bedingungen können wir dir nicht vorstellen. Das liegt ganz einfach daran, dass wir hier über einen reinen Buchmacher mit einer offiziellen deutschen Sportwetten-Lizenz sprechen. Slot-Action wird grundsätzlich nicht angeboten, so dass es auch keinen entsprechenden .

rockwell b-scale hardness testing|rockwell hardness scale for aluminum